The decision to build the longest road tunnel in the world was made by the Norwegian Parliament in June 1992. The new major road between Oslo and Bergen runs between Aurland and Laerdal for a distance of 15 miles.

Due to the mountainous location, narrow roads, and several fjord crossings, the construction was permitted to cross a region of the country with relatively low levels of road and transport dependability.

The extension of a safe, ferry-free road link connecting Norway‘s two biggest cities includes the Laerdal tunnel. Because of the potential of rock falls in the area and the rough terrain, it was decided to construct a tunnel rather than repair existing roadways.

The tunnel was considered to be an environmentally responsible investment because it prevented the destruction of undeveloped natural areas of the terrain.

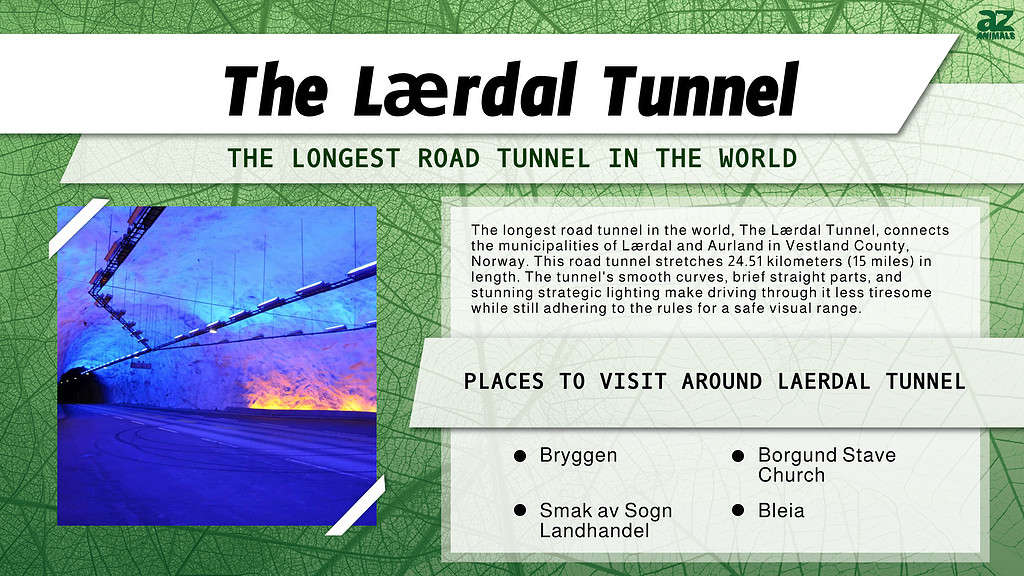

For the safety of travelers, the tunnel will immediately become impassable if a problem with the ventilation system or if there are any backups of traffic that cause large amounts of exhaust fumes. Image: FadiBarghouthy, Shutterstock

©FadiBarghouthy/Shutterstock.com

Constructing the World’s Longest Tunnel

Drilling, explosion, filling, and transport, as well as digging and landscaping, were the four primary phases of operation during the development of the Laerdal tunnel.

Both conventional drilling and blasting and computer-controlled drilling jumbos were used to drill the tunnel. It was crucial that the drilling and blasting work be done with remarkable precision in order to ensure that the tunnel sections meet more than six miles below the rock and 3,281 feet beneath the mountain.

The fixed survey locations that served as the foundation for all subsequent measurements inside the tunnel were identified using navigation satellites. Laser beams were used to show bearings inside the tunnel.

The drilling jumbo’s computer used laser beams to place the drilling machinery automatically in accordance with a predetermined pattern. There were three automated hydraulic drills in each drilling jumbo.

Throughout the tunnel, loading and moving materials were accomplished with wheel-mounted loaders. Dump trucks were used to transfer the excavated materials outside the tunnel.

Parallel to the tunneling work, permanent roadways were constructed inside the tunnel so that transport vehicles would have a solid, paved base to run on while it was being developed. This increased effectiveness and reduced pollution.

Skilled Psychologists worked with engineers to design the tunnel so that visitors wouldn’t find it boring.

Image: Jan Zabrodsky, Shutterstock

©Jan Zabrodsky/Shutterstock.com

Designing the Laerdal Tunnel

It was difficult for the Norwegian Public Roads Administration (NPRA) to construct the tunnel such that visitors wouldn’t find the 20-minute trip boring and lose focus.

In order to determine what could be changed to make the trip through the tunnel more enjoyable, a working group at SINTEF (the Industrial and Technological Research Association) led by skilled psychologists collaborated closely with the NPRA.

The Laerdal tunnel’s smooth curves and brief straight parts make driving through it less tiresome while still adhering to the rules for a safe visual range. The ideal lighting levels and design were determined using simulations.

The safe viewing distance is at least 3,281 feet at any particular location in the world’s longest tunnel. By using particularly expanded parts that are sufficiently big for buses and trains to turn without needing to reverse, the tunnel has been split into four segments.

There are three large caves in the tunnel for drivers to have a break or to alleviate claustrophobia.

Image: MaximBubu, Shutterstock

©MaximBubu/Shutterstock.com

Safety Features of Laerdal Tunnel

At the Laerdal tunnel, a lot of money was spent on equipment and safety measures. Any tunnel’s primary concern during construction was fire safety. The Laerdal tunnel cuts through dry rock, necessitating little water seepage sealing.

These techniques were utilized in a bus fire in the Ekeberg tunnel in 1996, one of the few locations where combustible plastic mats were needed for waterproofing. The tunnel roof’s temperature increased to more than 1821 degrees Fahrenheit due to the heat generation, which was in the range of 35.000kW, with no obvious damage to the tunnel cladding.

The Laerdal tunnel is equipped with a significant amount of emergency supplies despite the low probability of accidents and safe fire designs. In comparison to previous tunnels, emergency phones and fire extinguishers were placed more frequently.

The equipment used to monitor and check the functionality of the emergency supplies, traffic lights, radio links, ventilation systems, and other components cost several million Norwegian kroner.

. The Laerdal tunnel cuts through dry rock, necessitating little water seepage sealing.

Image: Marcin Cibor, Shutterstock

©Marcin Cibor/Shutterstock.com

The tunnel systems in the area are monitored and examined by the Laerdal monitoring center of the Norwegian Public Roads Administration. For the safety of the travelers, 200,000 rock bolts have been used to strengthen and secure the tunnel.

The tunnel will immediately become impassable if a problem with the ventilation system or if there are any backups of traffic that cause large amounts of exhaust fumes.

The monitoring center will immediately close the tunnel in the event of a traffic accident or other emergency. Radio announcements notify every car that enters the tunnel whether they should wait or maybe turn around and exit.

Ventilation

At a distance of 11 miles from the Aurland end of the tunnel, the tunnel is longitudinally ventilated by a single ventilation air exhaust shaft. A cleaning facility for the tunnel ventilation air was erected in a brief side tunnel around six miles from the Aurland end of the tunnel.

In order to ensure appropriate air quality all through the tunnel even during times of high traffic and to reduce the amount of air volume and power consumption needed to ventilate the lengthy tunnel, this facility filters the flowing air for important polluting elements. The air cleaning system will automatically activate when necessary based on constant monitoring of the tunnel’s air quality.

Where is the Laerdal Tunnel Located on a Map?

The Lærdal Tunnel, situated about 175-200 kilometers northeast of Bergen, Norway, connects the municipalities of Lærdal and Aurland in Vestland County. This road tunnel stretches 24.51 kilometers in length.

Here is the Laerdal Tunnel Located on a map:

The photo featured at the top of this post is © Marcin Cibor/Shutterstock.com

Thank you for reading! Have some feedback for us? Contact the AZ Animals editorial team.